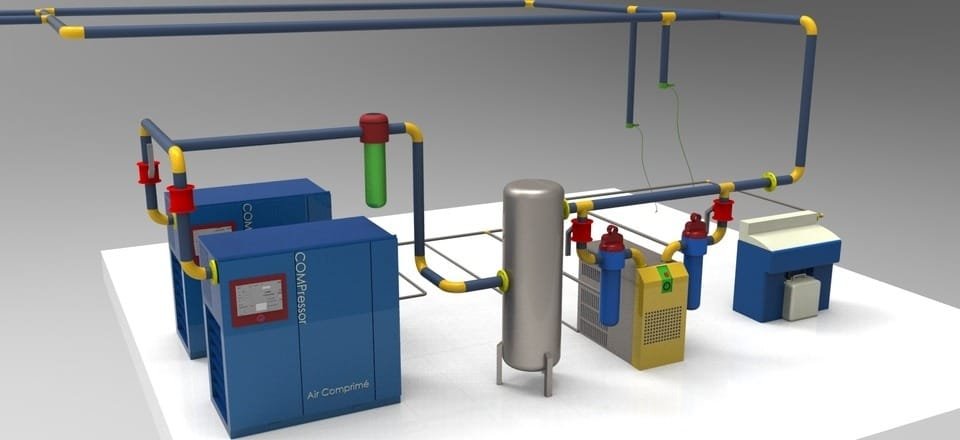

Compressed air is often called the fourth utility in industries because of its vital role in powering tools, equipment, and processes. But it comes with a hidden cost: compressed air systems are among the most expensive utilities in any plant, and a major reason is their high electricity consumption.

In many facilities, electricity can account for up to 70% of the total lifecycle cost of a compressed air system. That means if your system is not optimized, you could be losing a significant amount of money every single year.

Why Does This Happen?

There are several factors that make compressed air such a costly utility:

- Energy losses during compression.

- Air leaks that waste pressure.

- Running compressors at higher pressure than required.

- Oversized systems consuming more power than necessary.

- Poor maintenance practices.

Each of these issues quietly increases your electricity bills, often without you even realizing it.

What’s the Solution?

The good news is that energy costs in compressed air systems can be reduced by 20–30% with the right knowledge, techniques, and maintenance practices. But you need to know where and how to take action.

That’s exactly what we’ll be covering in our upcoming professional training program:

👉 “Advance Management of Compressed Air Systems”

This training is designed for professionals who want to:

- Identify energy waste in their compressed air systems.

- Learn best practices for reducing electricity consumption.

- Improve efficiency and save operational costs.

Final Word

Compressed air will always consume electricity, but whether it consumes too much depends on how well it is managed. If you want to cut costs, improve performance, and master the techniques of efficient compressed air management—our training is the right place to start.